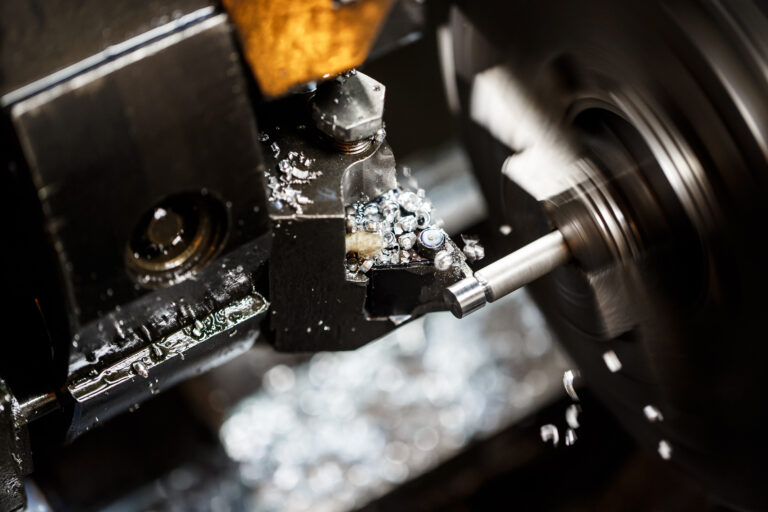

Machining parts are products obtained from various #machining processes like #turning, #milling, #drilling, and #grinding. As per the Machining Parts Manufacturer, they consist of material taken from raw plastic, #metal, or composite workpieces to obtain the required shape, size, and surface finish.

Read More: https://sites.google.com/view/indgirka/what-are-machining-parts-types-benefit-and-design-guide

Read More: https://sites.google.com/view/indgirka/what-are-machining-parts-types-benefit-and-design-guide

Machining parts are products obtained from various #machining processes like #turning, #milling, #drilling, and #grinding. As per the Machining Parts Manufacturer, they consist of material taken from raw plastic, #metal, or composite workpieces to obtain the required shape, size, and surface finish.

Read More: https://sites.google.com/view/indgirka/what-are-machining-parts-types-benefit-and-design-guide

0 Комментарии

0 Поделились

16 Просмотры

0 предпросмотр